An electrical wiring system is the process of connecting cables and wires to connected equipment such as fuses, switches, sockets, lights, fans, other electrical equipment, etc. To the main distribution board, which is a particular structure attached to the utility pole to ensure an uninterrupted power supply.

Have a look at types of electrical wiring and general rules

General Rules For Electrical Wiring

- A two-pole linked main switch and a fuse unit must be installed near the point of entrance of supply cables on every installation. If one pole in a two-wire arrangement is permanently earthed, no fuse, switch, or circuit breaker should be installed on that pole. In a three-phase supply, a three-pole switch and fuse unit should be used.

- The conductor used must be of significant length to safely carry load current.

- The conductors installed must be safe in every way.

- A distribution fuse board must be attached to each sub-circuit.

- Each line (phase or positive) must be protected by a fuse with the appropriate rating, according to the requirement.

- In earthed conductors, no fuse or switch is required.

- A separate means of isolation, such as a switch, must be provided for each circuit or equipment.

- All gear that requires attention must be equipped with a means of access.

- Light and fan wiring, as well as power wiring, must be kept separate in any building.

- The bottom of a switchboard should be 1 to 25 meters above the ground level.

- All plugs and socket-outlets must be of the 3-pin type, with the corresponding pin of the socket permanently attached to the earthing system.

- Lamp holders in bathrooms must be made of insulating materials and equipped with a protective shield, and the earth continuity conductor must not be less than 7/0.915 mm in diameter.

- All metal sheaths or conduits for any wiring, as well as the metal covers of all-consuming devices or appliances, must be adequately earthed to prevent electrical shock from leakage or insulation failure.

- Each sub-circuit must be safeguarded by a fuse or automatic circuit breaker against excessive current (which can arise due to overload or insulation failure). To avoid risk, all live conductors must be insulated or otherwise protected.

- Before turning on the power, the installation must be thoroughly inspected.

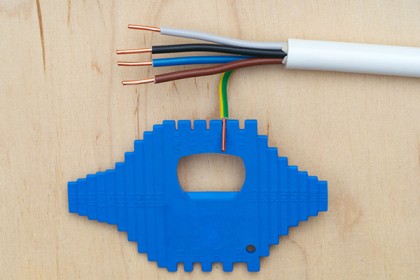

Electrical Wiring Systems when taking Connection to Home Joint Box

1. Connections to appliances are created using joints in this wiring style. Joint boxes with appropriate connections or joint cutouts are used to create these joints. This style of wiring does not necessitate a large number of cables.

2. Looping System: This wiring approach is widely utilized in the industry. Lamps and other appliances are linked in parallel so that they can all be regulated separately. The feed conductor is looped in by bringing it directly to the terminal and then carrying it forward to the next point to be fed when a connection is required at a light or switch.

5 Different Types of Electrical Wiring For House

- Cleat Wiring

This wiring is made up of braided and compounded PVC insulated wires or regular VIR. They’re attached to the walls and ceilings by grooved porcelain cleats, wood, or plastic. Because it is a temporary wiring system, it is not suitable for home use. Furthermore, wiring is rarely employed these days. - Casing and Capping Wiring

The cable is routed through grooves in a wooden housing. The wood casing is made in such a way that it has a required set length and parallel grooves for the cables to pass through. Screws are used to secure the wooden casing to the walls or ceiling.

A wooden cap with grooves is placed on top of the cables after they have been fitted inside the grooves of the casing. This is likewise a low-cost wiring design, but short circuits pose a significant risk of fire. - Batten Wiring

A single electrical wire or a group of wires is put over a wooden batten in this method. The wires are secured to the batten with a brass clip and placed at a 10 cm horizontal and 15 cm vertical gap. - Lead Sheathed Wiring

Conductors are insulated with VIR and covered with a lead aluminum alloy outer sheath that includes around 95 percent lead in lead sheathed wiring. The metal sheath protects cables from mechanical damage, moisture, and corrosion caused by the environment. - Lead Sheathed Wiring

Two types of electrical wiring according to the pipe installation

A) Conduit wiring on the surface when GI or PVC conduits are put on walls or roofs. At regular intervals, the conduits are secured to the walls with a 2-hole strap and base clip. The conduits are lined with electrical lines.

B) Wiring in the conduit that isn’t visible concealed conduit wiring occurs when the conduits are hidden inside the wall slots or carved brick wall. The conduits are lined with electrical lines. This is popular because it is more durable and attractive to the eyes.

When wiring isn’t installed correctly or isn’t properly maintained, it can lead to dangerous circumstances like electrical fires. So, when installing electrical wires and cables, it is essential to take extra care.

Do Check Out This: Top 6 Construction Tips For Your New House